How does DMLS work?

DMLS, or Direct Metal Laser Sintering, is an advanced additive manufacturing technology that uses a high-powered laser to fuse metal powder into complex, high-strength components layer by layer.

1

Laser selectively melts metal powder.

2

Laser selectively melts metal powder.

3

Laser selectively melts metal powder.

Why choose DMLS?

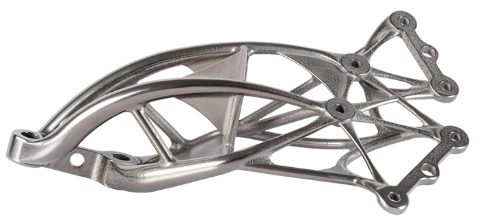

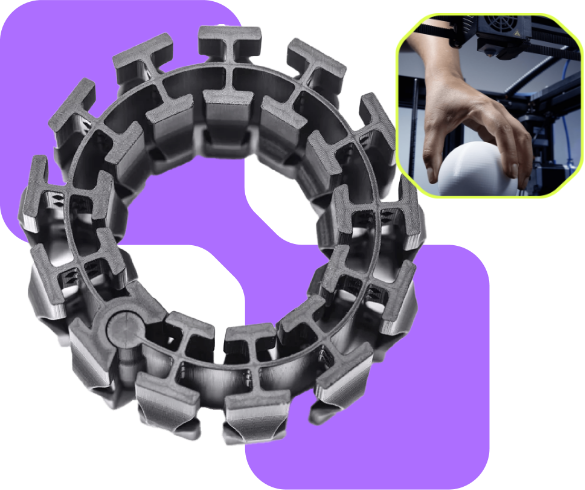

Complex Geometries

Achieve designs impossible with traditional methods

Material Efficiency

Minimize waste with precision powder usage.

High Strength

Produce durable parts with superior mechanical properties.

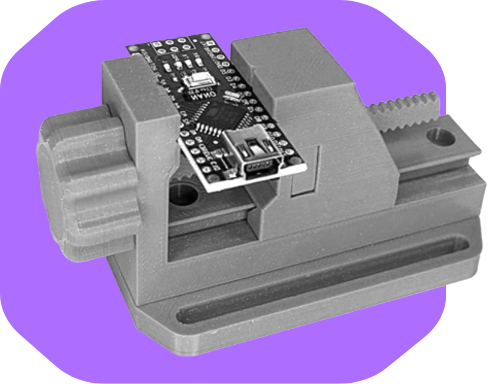

Customizable Solutions

Tailor parts for aerospace, automotive, and healthcare.

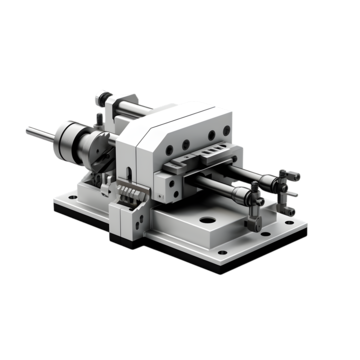

Applications